Global Consumption of Galvanized Profiles is Increasing! Why?

In recent years, the consumption of galvanized profiles has witnessed significant growth worldwide. This upward trend is not just a passing phase; it’s driven by several important factors that make galvanized profiles an essential material in various industries. From construction to automotive manufacturing, galvanized profiles are being utilized for their durability, cost-effectiveness, and environmental benefits. In this blog, we will explore the reasons behind the increasing global demand for galvanized profiles and why this trend is expected to continue.

Superior Corrosion Resistance

One of the key factors contributing to the rising demand for galvanized profiles is their excellent resistance to corrosion. Galvanized steel, which is coated with a layer of zinc, provides an effective barrier against moisture, oxygen, and other corrosive elements. This makes it ideal for applications in outdoor environments, coastal regions, and industrial settings where exposure to corrosive agents is common.

With climate change causing more frequent extreme weather conditions, industries are seeking materials that can withstand harsher environments. Galvanized profiles are an attractive solution due to their long-lasting protection against rust and corrosion, which significantly reduces maintenance costs over time.

Sustainability and Eco-friendly Benefits

Sustainability has become a central theme in construction, manufacturing, and infrastructure development. As industries strive to reduce their environmental impact, galvanized profiles are emerging as a popular choice. The zinc coating on galvanized steel not only prevents corrosion but also promotes recyclability. Galvanized steel can be recycled without losing its structural integrity, making it a more environmentally friendly option compared to other materials.

Furthermore, the long lifespan of galvanized profiles means fewer replacements and less waste. This is particularly important in industries like construction, where materials are expected to last for decades. As governments and organizations push for sustainable practices, the demand for galvanized profiles continues to rise globally.

Cost-Effectiveness in the Long Run

While the initial cost of galvanized profiles may be higher than some other materials, their long-term cost-effectiveness is undeniable. The durability and corrosion resistance of galvanized profiles mean they require less maintenance and replacement, saving businesses significant amounts of money over time. In industries such as construction, infrastructure, and automotive manufacturing, minimizing maintenance costs is a major priority, which makes galvanized profiles a smart investment.

In addition to their long-term cost savings, galvanized profiles also reduce the need for additional coatings or finishes, further lowering overall project costs. This makes galvanized profiles an economically viable choice for both small and large-scale projects.

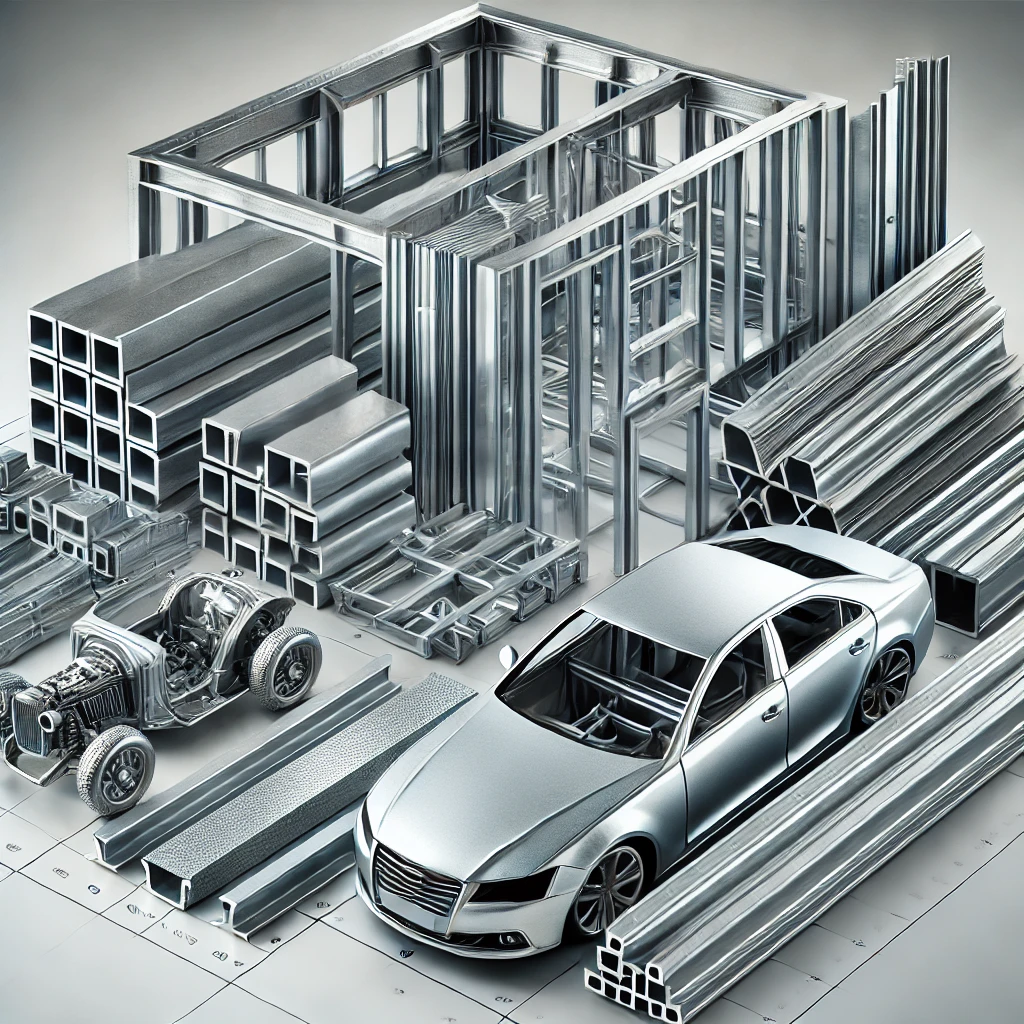

Versatility in Various Industries

Another reason for the growing consumption of galvanized profiles is their versatility. Galvanized profiles are used in a wide range of applications across various industries, including:

- Construction: Galvanized profiles are used for structural steel framing, roofing, and reinforcement bars. Their resistance to corrosion makes them ideal for building materials exposed to outdoor elements.

- Automotive Manufacturing: Galvanized steel is widely used in car bodies, chassis, and underbody components to prevent rust and extend the life of vehicles.

- Infrastructure Development: Galvanized profiles are used in bridges, highways, and utility poles, where durability and corrosion resistance are critical.

- Agriculture: Galvanized profiles are often used in farming equipment and structures like greenhouses and fencing due to their resistance to environmental wear.

The wide range of applications across multiple sectors has significantly contributed to the growing demand for galvanized profiles globally.

Global Infrastructure Boom

A key driver behind the increasing consumption of galvanized profiles is the ongoing infrastructure boom, particularly in developing economies. Countries around the world are investing heavily in infrastructure development, including roads, bridges, and residential buildings. Galvanized profiles are highly favored in these projects due to their durability, strength, and resistance to the elements.

As urbanization accelerates and more infrastructure projects are undertaken, the demand for galvanized profiles is expected to continue to rise. Galvanized profiles offer the strength and protection required for large-scale construction projects, making them indispensable in modern infrastructure development.

Technological Advancements in Galvanizing Processes

Advancements in galvanizing technologies have also played a role in the increased use of galvanized profiles. New, more efficient galvanizing techniques have improved the quality and durability of galvanized steel while reducing costs. Innovations such as dual-coating galvanizing, zinc-aluminum coatings, and advanced surface treatments have further enhanced the performance of galvanized profiles, making them an even more attractive option for various applications.

These technological improvements have made galvanized profiles more accessible to industries that may have previously considered them cost-prohibitive. As manufacturing processes continue to evolve, the global consumption of galvanized profiles is expected to increase even more.

Conclusion

The growing global consumption of galvanized profiles is driven by a combination of factors, including superior corrosion resistance, sustainability, long-term cost savings, versatility across industries, and ongoing infrastructure development. As the world continues to prioritize durability, environmental impact, and cost-efficiency, galvanized profiles will play an increasingly vital role in construction, manufacturing, and infrastructure sectors.

With the advantages they offer, it is clear why galvanized profiles are in high demand worldwide, and this trend is set to continue into the future. Whether for protecting infrastructure from corrosion or ensuring the longevity of products, galvanized profiles are poised to remain an essential material for industries worldwide.