What are the Disadvantages of Aluminium Foil Glass Wool?

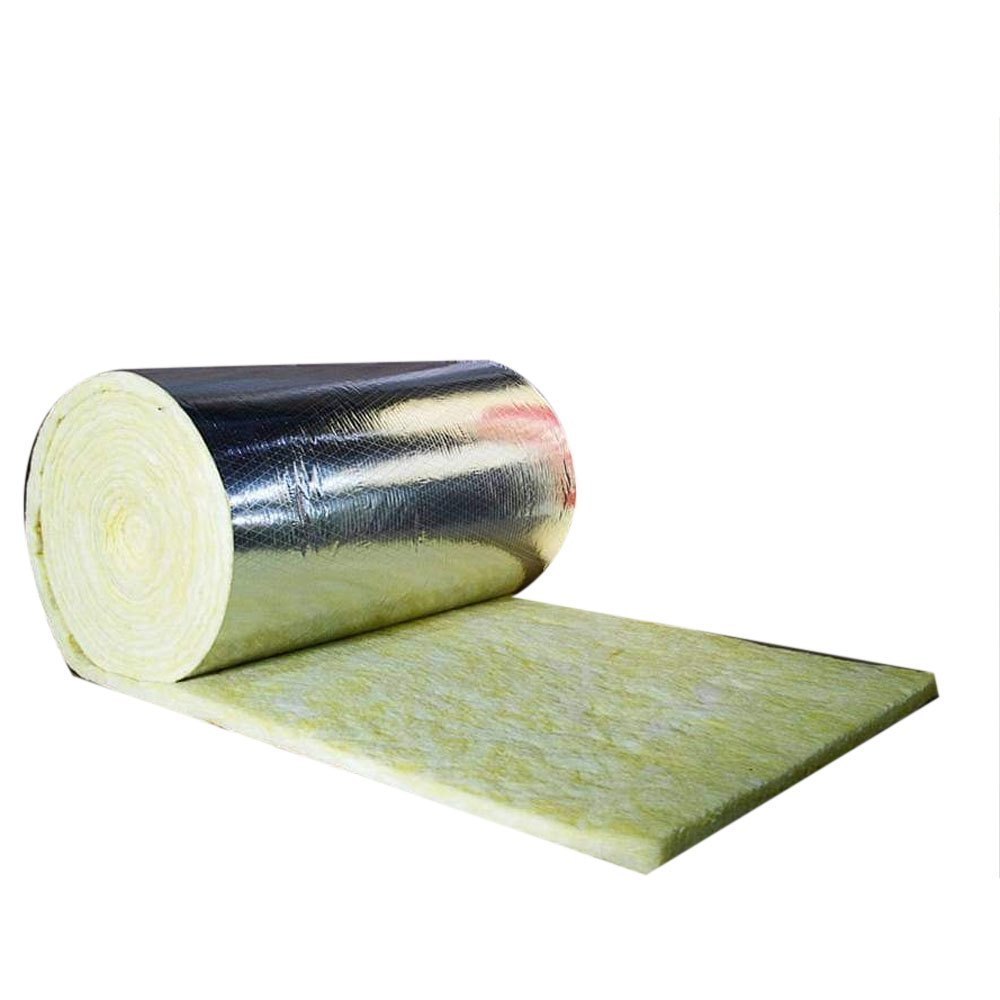

While aluminium foil glass wool is a highly effective insulation material offering numerous benefits, it is not without its limitations. Before deciding if it’s the right choice for your project, it’s important to be aware of some of the potential disadvantages of this material. Understanding both the pros and cons will help you make an informed decision.

Here are the key disadvantages of aluminium foil glass wool:

1. Health and Safety Concerns

Aluminium foil glass wool is made from tiny glass fibers, which can pose health risks if proper precautions aren’t taken during installation. When disturbed, these fibers can become airborne, and if inhaled, they may irritate the respiratory system or skin. This is particularly important for installers or anyone handling the material during the construction process.

- Skin Irritation: The tiny glass fibers can cause irritation if they come in contact with the skin, leading to itching or rashes.

- Respiratory Issues: Inhaling the dust from glass wool can cause respiratory irritation, especially when the material is disturbed or cut.

Precautionary Measures: Wearing protective gear such as gloves, masks, and goggles is essential when handling aluminium foil glass wool to reduce the risk of irritation or injury.

2. Potential for Moisture Absorption Over Time

While the aluminium foil layer offers moisture resistance, glass wool can still absorb moisture if the foil is damaged or if there is prolonged exposure to high humidity. When aluminium foil glass wool absorbs moisture, its insulation properties decrease, leading to reduced thermal and acoustic efficiency.

- Reduced Effectiveness: Moisture absorption can significantly lower the material’s insulating performance, resulting in higher energy costs.

- Mold Growth: If moisture is trapped within the insulation for an extended period, it may lead to mold or mildew growth, which can cause health issues and damage the structure.

3. Compression and Settling

Although aluminium foil glass wool is generally durable, over time, it can lose its effectiveness if compressed. This is especially true if the insulation is exposed to heavy loads or not installed properly. Compression of glass wool fibers reduces the amount of air trapped between the fibers, which diminishes the insulation’s ability to resist heat flow.

- Reduced Insulation Value: As the material settles or compresses, its thermal and soundproofing performance decreases.

- Less Effective Over Time: If not properly maintained, compressed insulation will lose its long-term effectiveness and may need to be replaced.

4. Cost

While aluminium foil glass wool offers long-term savings through improved energy efficiency, its initial installation cost can be higher than other insulation materials. For budget-conscious projects, this could be a drawback, especially when compared to less expensive options like fiberglass batt insulation.

- Upfront Cost: The price per square meter can be higher than traditional insulation materials, which may deter some homeowners or builders.

- Additional Costs for Installation: If you hire professionals for installation, the costs could increase due to the need for protective gear and the complexity of handling the material.

5. Environmental Impact of Manufacturing

Although aluminium foil glass wool is made from recycled glass, the manufacturing process still consumes significant energy and resources. The production of aluminium foil also has environmental implications due to the energy-intensive process of mining and refining bauxite.

- Energy Consumption: The production of aluminium foil and glass wool requires energy, contributing to the material’s carbon footprint.

- Waste Generation: Manufacturing processes can generate waste materials, though some manufacturers are moving towards more sustainable and eco-friendly production methods.

6. Installation Complexity

While aluminium foil glass wool is relatively easy to install, it can still pose challenges in certain situations. Proper installation requires careful handling and cutting to ensure that the insulation fits tightly into spaces and does not get compressed. Improper installation can lead to gaps or air leaks, which can significantly reduce the insulation’s performance.

- Risk of Gaps: Incorrect installation can result in gaps, which reduces the insulation’s ability to retain heat or soundproof spaces.

- Professional Installation: While DIY installation is possible, professional installation may be required to ensure optimal performance and avoid potential issues with compression or gaps.

7. Fragility

Aluminium foil glass wool can be fragile, especially when it is exposed to impact or rough handling. The glass wool fibers can break down, and the foil can tear or wrinkle if not handled carefully. This fragility can lead to reduced performance if the insulation is damaged during transportation or installation.

- Damage During Handling: If the material is bent or crushed during transport or installation, it may not provide the desired level of insulation.

- Tearing of Foil: The aluminium foil layer, though protective, can tear if exposed to rough handling, diminishing its moisture-resistant properties.

8. Limited Use in Extreme Conditions

Although aluminium foil glass wool is effective in a wide range of applications, it may not be the best choice for extreme conditions. In environments with very high temperatures (such as industrial furnaces or boilers), the insulation may degrade or lose effectiveness. In these cases, more specialized insulation materials may be required.

- Not Ideal for Extreme Heat: While the material performs well in typical building applications, it may not be suitable for environments with sustained high temperatures.

- Potential Degradation: If exposed to extreme heat, the glass wool fibers or the aluminium foil may degrade, reducing the insulation’s efficiency.

Conclusion: Is Aluminium Foil Glass Wool Right for Your Project?

While aluminium foil glass wool offers numerous advantages, including excellent thermal insulation, soundproofing, and fire resistance, it does come with some disadvantages. These include health concerns during installation, potential moisture absorption, compression issues, and higher initial costs. Understanding these limitations will help you determine if it is the right insulation material for your specific needs.

If you are ready to enhance your building’s insulation with aluminium foil glass wool, make sure to weigh these pros and cons carefully. Consider professional installation to avoid common issues and maximize the material’s performance.