Can Crown Molding Crack Causes and How to Prevent It

Crown molding is a popular design feature used to add elegance and character to a room, but over time, even the most beautiful installations can experience cracking. Cracks in crown molding can be frustrating, especially when you’ve invested time and effort into creating a flawless finish. However, understanding the causes of these cracks and knowing how to prevent them can help you maintain your crown molding’s appearance for years to come.

In this blog, we’ll explore the common causes of crown molding cracks and provide helpful tips on how to prevent them.

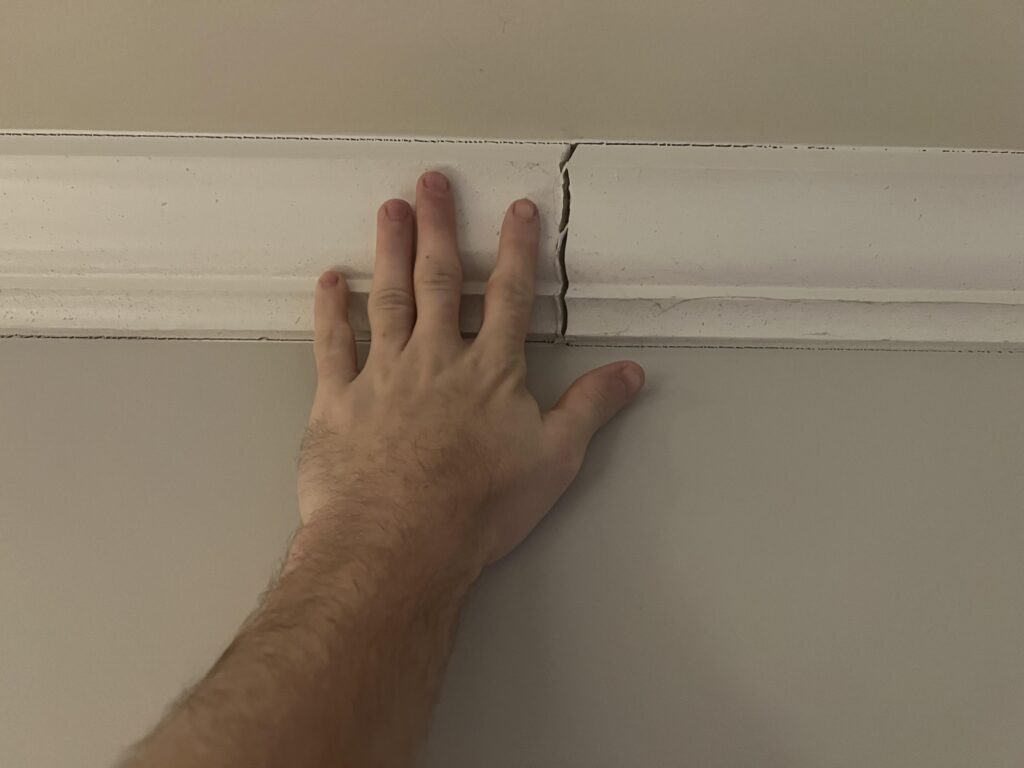

Common Causes of Crown Molding Cracks

Understanding the root causes of cracking can help you address the issue before it happens or deal with it effectively if it already exists. Here are the most common reasons for cracks in crown molding:

1. Poor Installation

One of the most common causes of cracking in crown molding is improper installation. If the molding is not correctly fitted, it can lead to tension in the material, causing it to crack over time. Poor installation can occur if:

- The angles were not cut correctly.

- The molding was not nailed or secured properly, leading to movement and stress on the material.

- The molding was installed too tightly against the wall or ceiling, which creates pressure.

2. Settling and Shifting of the Structure

As your home settles over time, it can cause slight movements in the walls and ceilings. These structural shifts may not be immediately noticeable, but they can result in the crown molding cracking, especially at the joints. Settling happens naturally in most homes, particularly in older houses, and can cause gaps or cracks in molding over time.

3. Humidity and Temperature Changes

Changes in temperature and humidity levels can cause building materials, including wood and plaster crown molding, to expand or contract. This natural movement can lead to cracking. In humid conditions, wood can absorb moisture and expand, while in dry conditions, it can shrink, creating stress on the molding. Similarly, extreme heat or cold can cause the material to expand or contract, leading to cracks.

4. Type of Molding Material

The material of the crown molding plays a significant role in its susceptibility to cracking. Wood molding is more prone to cracking, especially if it’s made from softer woods like pine. Plaster crown molding, while more durable, can also crack due to its brittle nature. Other materials, like foam and polyurethane, are less likely to crack but can still suffer damage under extreme conditions.

5. Improper Finishing

If the crown molding is not properly finished with paint or sealant, it can lead to cracking. The paint or finish applied to the molding helps to seal the material and protect it from environmental factors like moisture and temperature changes. If the finish is thin, uneven, or cracked, it can leave the molding vulnerable to further damage.

How to Prevent Crown Molding Cracks

While some cracking is inevitable, there are several steps you can take to prevent cracks from occurring in the first place, and to minimize damage if they do appear.

1. Use Proper Installation Techniques

To prevent cracks due to installation errors, it’s crucial to take the time to install the crown molding properly. Here are a few key installation tips:

- Measure Carefully: Accurate measurements will ensure that each piece of molding fits correctly, reducing stress on the material.

- Secure the Molding Properly: Ensure the molding is attached securely but not too tightly, allowing for slight expansion and contraction. Use nails or a nail gun to hold it in place, and make sure the nails are driven into the studs of the wall or ceiling.

- Angle the Cuts Correctly: Be sure to cut the molding at the proper angles to ensure a seamless fit at the corners.

2. Use Flexible Adhesives

In addition to nails, using a high-quality, flexible adhesive can help absorb any slight movement in the molding, preventing cracks from forming. The adhesive will provide additional support, especially in areas where there may be slight shifting due to settling or humidity.

3. Control Humidity and Temperature

Controlling the indoor climate can help reduce the chances of your crown molding cracking. If possible, use a humidifier or dehumidifier to maintain consistent humidity levels in the room. Keeping the temperature in the room relatively stable will also prevent the molding from expanding and contracting due to heat and moisture fluctuations.

4. Choose the Right Material

If you are concerned about cracking, consider choosing more durable materials for your crown molding, such as polyurethane, which is lightweight, flexible, and less prone to cracking than wood or plaster. Foam crown molding is another excellent option, as it is both lightweight and resistant to damage.

5. Proper Finishing and Maintenance

Once your crown molding is installed, ensure it is properly finished to prevent cracking from external factors. Use a high-quality primer and paint to seal the molding. For wood molding, consider using a polyurethane finish to help protect it from moisture and temperature changes. Be sure to inspect the molding regularly and touch up any chips or cracks in the finish to avoid further damage.

Repairing Cracked Crown Molding

Even with the best prevention techniques, cracks can sometimes occur. If you notice cracks in your crown molding, here’s how you can repair them:

- Fill the Crack: For small cracks, use wood filler for wood molding or spackling compound for plaster molding. Apply the filler to the crack and smooth it out with a putty knife.

- Sand the Area: Once the filler has dried, sand the area smooth with fine-grit sandpaper.

- Touch Up the Finish: After sanding, touch up the area with the appropriate paint or finish. For wood, apply a matching wood stain, and for plaster, repaint the molding.

Conclusion

Cracks in crown molding can occur for a variety of reasons, but with the right approach, they can be prevented or easily repaired. By ensuring proper installation, using the right materials, controlling environmental factors, and maintaining the finish, you can keep your crown molding looking beautiful and free from cracks for many years. If cracks do appear, quick action and regular maintenance can restore the molding to its original condition.