How Is Placo Made?

Placo, a leading brand in the construction industry, is well-known for its high-quality gypsum boards and plaster solutions. These materials are widely used for walls, ceilings, partitions, and other applications in residential and commercial buildings. But have you ever wondered how Placo products are made? In this blog, we will take a closer look at the manufacturing process of Placo products, highlighting the key stages that contribute to the creation of this essential building material.

The Manufacturing Process of Placo Gypsum Boards

The production of Placo gypsum boards involves a series of steps, from raw material selection to the final product ready for shipment. Below are the key stages of the manufacturing process:

1. Sourcing Raw Materials

The main raw material for producing gypsum boards is gypsum – a soft mineral that is primarily composed of calcium sulfate dihydrate. Gypsum is mined or extracted from quarries and is typically available in a powdery or rock form. It is abundant and readily available in many parts of the world, making it a cost-effective option for building materials.

In addition to gypsum, paper is another critical material used in the production of Placo boards. This paper is used to form the outer layers of the board and provide strength and durability.

2. Preparing the Gypsum Slurry

Once the gypsum is mined, it is processed into a fine powder and mixed with water to create a slurry. This slurry forms the core of the gypsum board. Other additives, such as starch, foam agents, and sometimes fiberglass, are also added to improve the properties of the board, such as fire resistance, water resistance, or soundproofing capabilities.

The slurry mixture is thoroughly blended to ensure uniform consistency, which is essential for the quality of the final product.

3. Forming the Board

The slurry is then poured onto a continuous production line, where it is spread between two sheets of paper. These paper sheets serve as the outer layers of the gypsum board. As the slurry is spread evenly, the board starts to take shape.

At this stage, the board is still in its soft and wet form, so it must be processed further to ensure it holds its shape and strength.

4. Drying and Hardening

After the board is formed, it moves through a drying kiln where the gypsum slurry undergoes a controlled drying process. The heat helps remove moisture from the slurry, turning it into solid gypsum. This process helps the gypsum board harden and gain its strength and rigidity.

The drying process is crucial in ensuring that the board becomes durable enough to withstand pressure, weight, and various environmental conditions.

5. Cutting and Shaping

Once the board has dried and hardened, it is cut into the desired dimensions using precision cutting machines. Placo products come in various sizes, thicknesses, and specifications depending on the needs of the project. The most common size is a 4×8 foot board, but custom sizes are also available.

The edges of the boards may also be shaped or beveled to make installation easier and to improve the appearance once the board is in place.

6. Quality Control and Testing

Before the Placo boards are ready for distribution, they undergo rigorous quality control checks. These tests assess various properties of the boards, including their strength, fire resistance, moisture resistance, and soundproofing performance. The goal is to ensure that the final product meets the industry standards and the company’s high-quality benchmarks.

Some boards, for example, may be subjected to fire testing to ensure they can withstand high temperatures, while others may be tested for moisture resistance to ensure they perform well in humid environments.

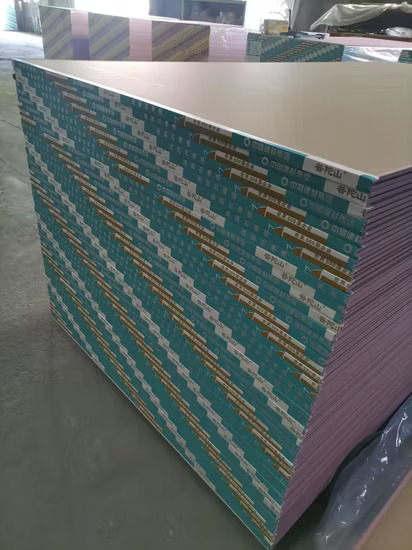

7. Packaging and Shipping

Once the boards pass all quality checks, they are carefully packaged and prepared for shipment. Placo gypsum boards are stacked and wrapped securely to prevent damage during transport. The finished products are then sent to distributors, construction companies, and suppliers across the region.

Conclusion

The production of Placo gypsum boards involves a meticulous and detailed process, from the sourcing of raw materials to the final product ready for installation. Each step in the process is designed to ensure the quality, durability, and performance of the boards in various construction applications.

Placo products are known for their consistent high quality, making them a popular choice for builders, architects, and contractors. Whether you are building a new home, office, or commercial structure, Placo boards provide reliable and effective solutions.

Need Assistance with Placo Products?

If you’re looking for the best Placo solutions for your next project, don’t hesitate to reach out to us. Our team of experts can help you select the right type of board for your needs, ensuring the success of your construction project.

Contact us today for personalized advice, quotes, and guidance on how to integrate Placo products into your upcoming ventures!